Our Technology

Our valve test equipments use various technologies for accurate and faster testing. You may find them below.

Vacuum Technology:

We are proud that we are one of the very few manufacturers in the world who can provide valve test benches with an effective vacuum facility. This has very obvious advantages. Please read below.

Air entrapment is a common problem during valve testing and some people do not pay much attention to it. Please go through the following illustration for better understanding.

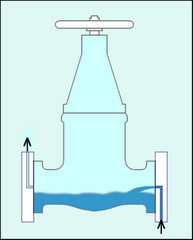

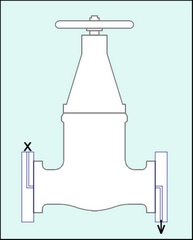

Testing Process without Vacuum

| A) When the testing fluid is being filled, the air inside the |

B) When the fluid reached half the level, fluid is |

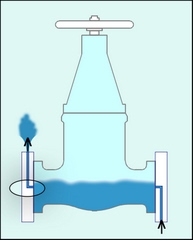

C)

The vent is closed and the water is pressurised. The |

D) When the required test pressure is reached, the air is also at the same pressure which is usually high enough to initiate a projectile. |

As you can see, the low pressure pump can fill only less than half of the valve after which the air is being compressed. Which means, the high pressure pump has to do the job and this has a very small flow rate. So, a large valve like a 36" #600 valve takes even hours to reach the test pressure. And most importantly this is with a huge risk of compressing the air !

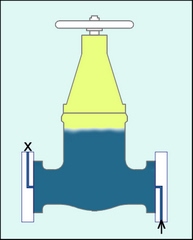

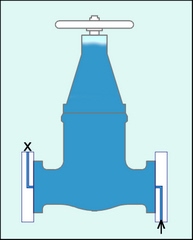

Testing Process with Vacuum

| A)

The vent remains closed and all the air inside the valve |

B) Now, the valve is filled with a low pressure pump. This is what reduces the testing time. |

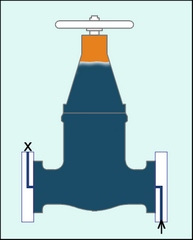

C) The valve is now pressurised to the recommended test pressure. Virtually no air is present and hence no risk. |

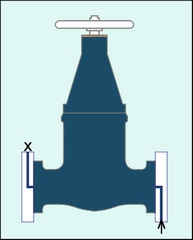

When the air is evacuated from the valve, the valve is filled with only water which is practically non compressible. Also, since the whole valve is filled during the low pressure filling phase, very less volume is left for the high pressure pump to fill up. And hence the pressure starts rising immediately and rapidly. The valve that could take more than 30 minutes to pressurise without vacuum, can be done in 90 seconds.

Good Testing Practice

As a good testing practice, the valve is bleeded off the air through the stem gland or vent holes in the valve while filling with water.

Vacuum can substitute this and in situations when a vent is not available like in the case of a check valve, vacuum is the only way to get off the air.

*All data indicated are for reference only.