Vertical Test Stands

Horizontal Test Benches

UTB-85-12

The machine structure consists of a screw rod with one end connected to the top sealing plate and the other end free. The screw rod is driven by a hydraulic motor through a nut. This movement is used to adjust the distance between the sealing plates according to the face to face distance of various sizes of valves. The whole top assembly including the drive system is mounted in an arm that can swing open to allow the loading and unloading of valves from top using a crane. The bottom side is fixed and houses a short stroke hydraulic cylinder capable of generating the rated clamping force. The bottom side also has a set of claws that can be manually moved to clamp the safety valve or a shut off valve by the flange.

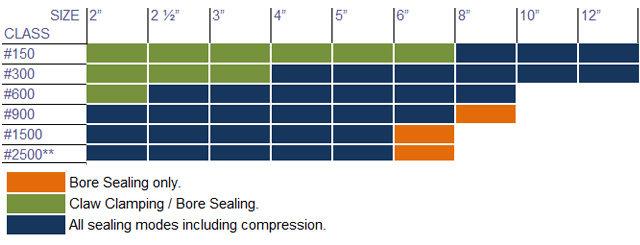

This type of structure allows you to test all types of valves i.e. flanged end (face sealing), butt weld, socket weld (bore sealing) and flanged end safety relief valves (claw clamping).

| Structure type | : | Bottom Claws with Top Swing Arm. |

| Max reaction force | : | 85 Tons. |

| Sealing | : | Face sealing & Bore sealing. |

| Max distance b/w faces | : | 950 mm. |

| Min distance b/w faces | : | 150 mm. |

| Distance b/w columns | : | 900 mm. |

| Max diameter within claws | : | 625 mm.. |